HybriGenix Project

Description:

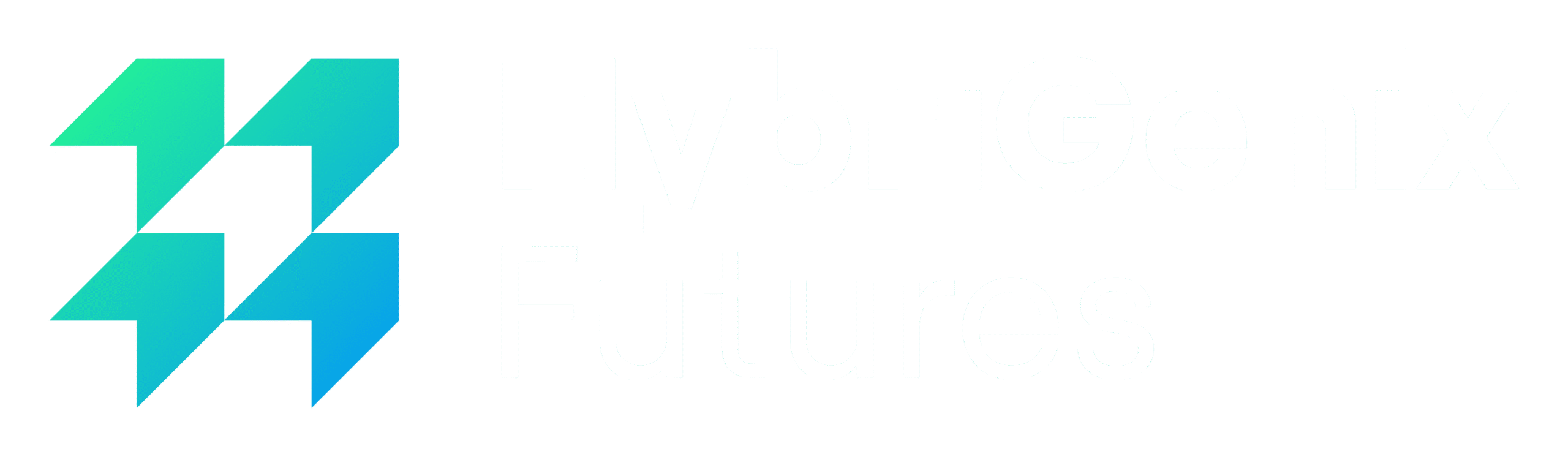

This infographic presents HybriGenix’s overall transition from clean power to hydrogen growth. On the left, Phase 1 – Alberta Pilot highlights a 30 MW combined cycle power plant using a Siemens SGT-600 turbine with ≥97% availability. On the right, Phase 2 – Hydrogen Expansion illustrates the future scale-up to ~1,200 kg/day of hydrogen through multiple low-carbon pathways, including electrolysis, SMR with carbon capture, and pyrolysis.

Together, these phases demonstrate how today’s proven power generation provides revenue and operational confidence, while building the foundation for tomorrow’s hydrogen economy.

Phase 1

Phase 1 focuses on delivering reliable, clean electricity at commercial scale. Using a Siemens SGT-600 gas turbine in a combined cycle configuration with a heat recovery steam generator (HRSG), the facility generates 30 MW of net clean power while achieving ≥97% plant availability.

This stage proves the technical and economic viability of the project. It generates early revenue through grid sales and establishes a hydrogen ready platform that will support the transition to Phase 2. In short, Phase 1 is both a proof of concept and a revenue generator, designed to build trust with partners and stakeholders.

Phase 2

Phase 2 represents the scale up of hydrogen production to approximately 1,200 kilograms per day. Unlike a single technology approach, this stage integrates multiple low carbon pathways:

Green hydrogen through electrolysis powered by renewable electricity.

Blue hydrogen via SMR combined with high-efficiency carbon capture.

Teal hydrogen through pyrolysis, producing hydrogen and solid carbon without CO₂ emissions.

By combining hydrogen production with power generation and carbon capture, Phase 2 maximizes infrastructure value while enabling entry into the growing hydrogen and carbon markets. This stage is where HybriGenix leverages proven assets to achieve long term growth and impact.

Green Hydrogen – Electrolysis

Renewable power splits water into H₂ through electrolysis, producing zero direct CO₂ emissions.

- 100% renewable energy

- Zero CO₂ emissions

- Higher cost today

Blue Hydrogen – SMR + Carbon Capture

Natural gas is converted to hydrogen while capturing ~90% of CO₂ emissions.

- Mature and proven technology

- Lower cost than green hydrogen

- Dependent on natural gas supply

Teal Hydrogen – Pyrolysis

Gas is thermally decomposed into hydrogen and solid carbon, avoiding CO₂ emissions.

- No CO₂ emissions

- Valuable solid carbon byproduct

- Still at demonstration stage

The HybriGenis solution is the integration of methane reforming technology with gas turbine operations to enable simultaneous hydrogen production and electricity generation. This innovative approach leverages waste heat from the gas turbine to drive the methane reforming process, which converts methane (CH4) into hydrogen (H2) and solid carbon (C). The process involves heating methane to high temperatures in the absence of oxygen, causing it to undergo chemical decomposition, resulting in hydrogen and solid carbon as byproducts.

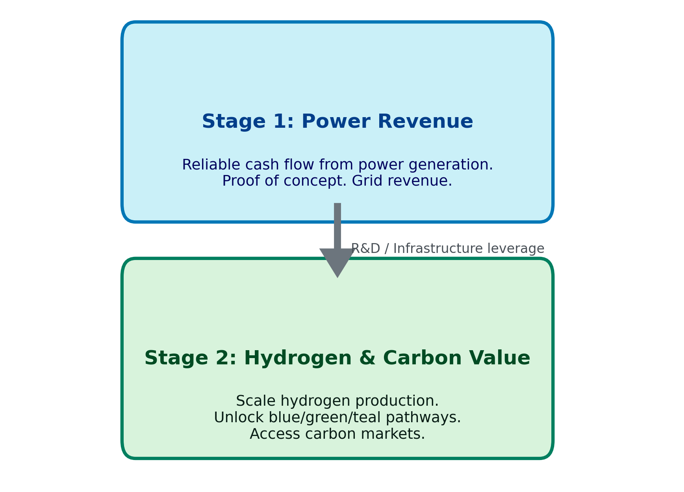

Investor Model

From power revenue today to hydrogen and carbon value tomorrow.

Problem Addressed and Market Need:

The HybriGenix solution addresses the pressing need for low-carbon energy production in various sectors, including power generation, industrial processes, and transportation.

By enabling simultaneous hydrogen production and electricity generation from natural gas, the solution offers a transformative improvement compared to current practice by maximizing resource utilization and minimizing emissions.

Direct GHG Reductions:

The primary direct GHG reduction comes from the production of hydrogen through methane pyrolysis, which emits significantly lower carbon dioxide (CO2) compared to traditional steam methane reforming processes. By utilizing waste heat from the gas turbine to power the methane reforming process, the project minimizes energy inputs and emissions associated with hydrogen production.

Additionally, the combustion of hydrogen as a clean fuel in the gas turbine results in lower emissions of CO2 and other pollutants compared to conventional natural gas combustion.

Displacement of Higher-GHG Products:

The use of hydrogen produced from methane pyrolysis displaces the need for hydrogen derived from higher-GHG sources, such as steam methane reforming with carbon capture and storage (SMR-CCS). This displacement contributes to overall GHG reductions by avoiding emissions associated with conventional hydrogen production methods.

Enabled GHG Reductions:

The adoption of the proposed solution enables GHG reductions in various sectors, including power generation, industrial processes, and transportation. By providing a scalable and efficient method for hydrogen production, the solution facilitates the integration of hydrogen as a clean energy carrier in diverse applications, leading to broader GHG reductions across the economy.